The rapid growth of e-commerce and its projected dominance in retail has prompted large and small businesses to invest in automated e-commerce fulfillment processes. Brick-and-mortar retailers like Walmart and Kroger recognize the importance of integrating automation into their operations to stay competitive. They are investing heavily to capture market share.

In this article, we will explore how automating your pick, pack, and ship processes can help you overcome challenges associated with manual operations. Additionally, we will delve into the role of custom software in enhancing automation and provide eight key considerations to keep in mind before integrating this technology into your business.

The Need for Automation:

Manual pick, pack, and ship processes often lead to order inaccuracies, high employee turnover, and unpredictable costs of goods sold (COGS). With consumers demanding sites and marketplaces that allow a wide variety of products in one cart, the need for warehouse automation becomes crucial. More SKUs equals a greater chance of a picking error and fewer boxes packed per hour. Fortunately, automation hardware is continually evolving and improving, with industry-specific systems available to suit diverse requirements.

The true potential of automation lies in leveraging custom software, which adds layers of protection to your business, enables integration with existing marketplaces, and may even pave the way for new revenue streams within your company.

8 Considerations When Automating Your Pick, Pack, & Ship Process:

- Shipping Carrier Flexibility:

When automating fulfillment, it is essential to consider building an API that seamlessly integrates with carriers such as UPS, FedEx, and Last Mile partners. Your software should factor in transit times, pricing, box dimensions, and volume discounts to recommend the optimal mix of carriers. Customers value less packaging, tracking transparency, and high on-time rates, so your software must help you consistently improve these metrics. - Customer Segmentation:

Segmenting customers based on lifetime value (LTV), order size, or transit time can enhance the fulfillment experience. For instance, high-value customers may require special handling, while somebody could pack first-time customers separately for a memorable unboxing experience. Segmentation can also allow you to be proactive for customers who have experienced delivery issues when a secondary package inspection may be warranted. - Weather Forecast Impact:

Upcoming weather forecasts may lead to changes in packaging materials or when you choose to fulfill orders for a particular geographical area. Accurate reporting can lower packaging costs and identify potential delays. You can optimize your fulfillment schedule and improve the customer experience by leveraging this information. - Gradual Automation:

Automation doesn’t have to be an all-or-nothing game. If your company primarily sells a handful of products, automating the pick and pack process for those specific items and adding others manually as a phased approach can be effective. This gradual implementation is particularly beneficial for small and mid-sized companies. Making small but steady improvements around pick accuracy, boxes packed per hour, and warehouse inventory control will move the needle.A food delivery company was able to apply automation to pick orders with over 72 possible SKUs and multiple items per order. - Trainability of the Software:

It’s crucial to overcome employee resistance and ensure successful integration early on. Automation comes with some process changes that your staff may not welcome at first. This can be amplified if the software they engage with is cumbersome. The new software should be intuitive, facilitating cross-training for current and new employees. Consider utilizing a user interface (UI) that includes similarities to other software that people are familiar with for quicker adoption. Minimize redundant entries and steps that lead to user frustration. - Cohesion with Existing Technologies:

Consider how new automated processes align with your existing technologies. For instance, you may already have excellent warehouse inventory management software. A unified strategy ensures that adding new software enhances your business’s overall efficiency and prolongs the effectiveness of your existing infrastructure. - Turning fulfillment into a Product:

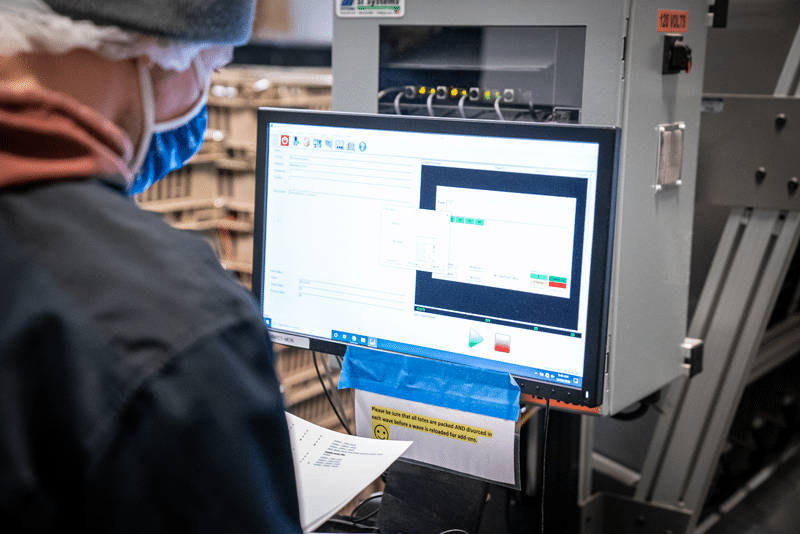

Automated e-commerce fulfillment can become a revenue stream by offering your new efficiencies as third-party order fulfillment services. This approach not only diversifies your income but also creates partnerships that can be highly lucrative. Retailers are researching how to reduce pick and pack errors. They understand how valuable this KPI is and may prefer to hire you for the job. Partners can connect to your software to easily, quickly, and securely connect business processes, products, content, and data.A manager is running a custom report before automating the pick, pack, and ship process for third party fulfillment. - Warehouse Dimensions:

The dimensions of your warehouse play a vital role in determining the automation solutions you can implement. Before deploying warehouse automation, your team should consider the room shape, square footage, and ceiling height. If space is limited, a modular approach to automation can ensure core processes remain effective while allowing scalability in a larger warehouse later.

In a rapidly evolving retail landscape, automating your e-commerce fulfillment should be considered for staying competitive and meeting customer expectations. Businesses can successfully integrate automation into their operations by leveraging custom software and evaluating the eight key considerations outlined in this article.

Toro Async has created successful warehouse automation features across multiple industries. To schedule a meeting and discuss your automation needs please click here.